We support business and individuals from early concept through to production-ready solutions, delivering robust, function-driven designs backed by practical engineering insight. Our services combine engineering led product design, CAD development and industrial 3D printing to create components and assemblies that are optimised for performance, manufacturability and real-world use.

From Concept to Functional Reality

Engineering-Led Product Design, CAD & 3D Printing

Who are we?

ACT3D, located on the Cambridgeshire Suffolk boarder, is a dependable and cost-effective product design, CAD and 3D printing consultancy, providing practical engineering support from initial concept through to delivery. Founded by a qualified product design engineer with extensive industry experience, we work with businesses, innovators and technical teams to develop functional, production-ready products and components.

Alongside our design and additive manufacturing capabilities, we bring years of hands-on experience in CNC machining and manufacturing. This allows us to consider downstream production from the outset, advising on geometry, tolerances and features to ensure designs are machining-friendly and ready for scale. By designing with manufacture in mind, we help reduce complexity, minimise costs and smooth the transition from prototype to production.

We deliberately limit the number of projects we take on at any one time, allowing us to fully engage with each brief and give careful consideration to performance, manufacturability and real-world use. Regardless of project size or complexity, we communicate clearly, avoid unnecessary jargon and maintain full transparency throughout the design process.

Ready to Engineer Your Next Project?

1

Product Design & CAD

Engineering-led product design and CAD development, from early concepts through to production-ready models. Designs are created with function, manufacturability and real-world performance in mind.

2

Reverse Engineering

Accurate recreation and optimisation of existing components using modern CAD tools, allowing parts to be reproduced, improved or prepared for manufacture.

3

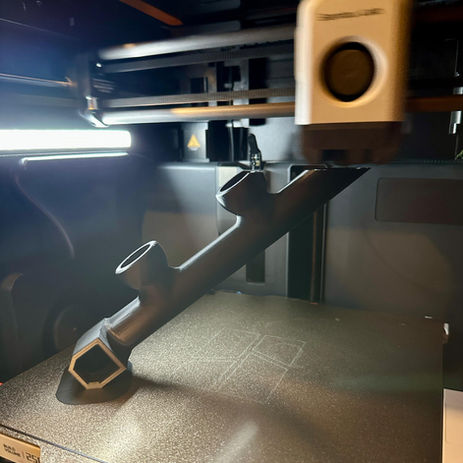

FDM 3D Printing

In-house FDM 3D printing for functional prototypes and low-volume parts. Ideal for fit checks, design validation and cost-effective iteration during development.

4

Manufacturing Support

Design-for-manufacture guidance drawing on years of CNC machining and production experience. We advise on features, tolerances and materials to help reduce cost and simplify the transition to manufacture.